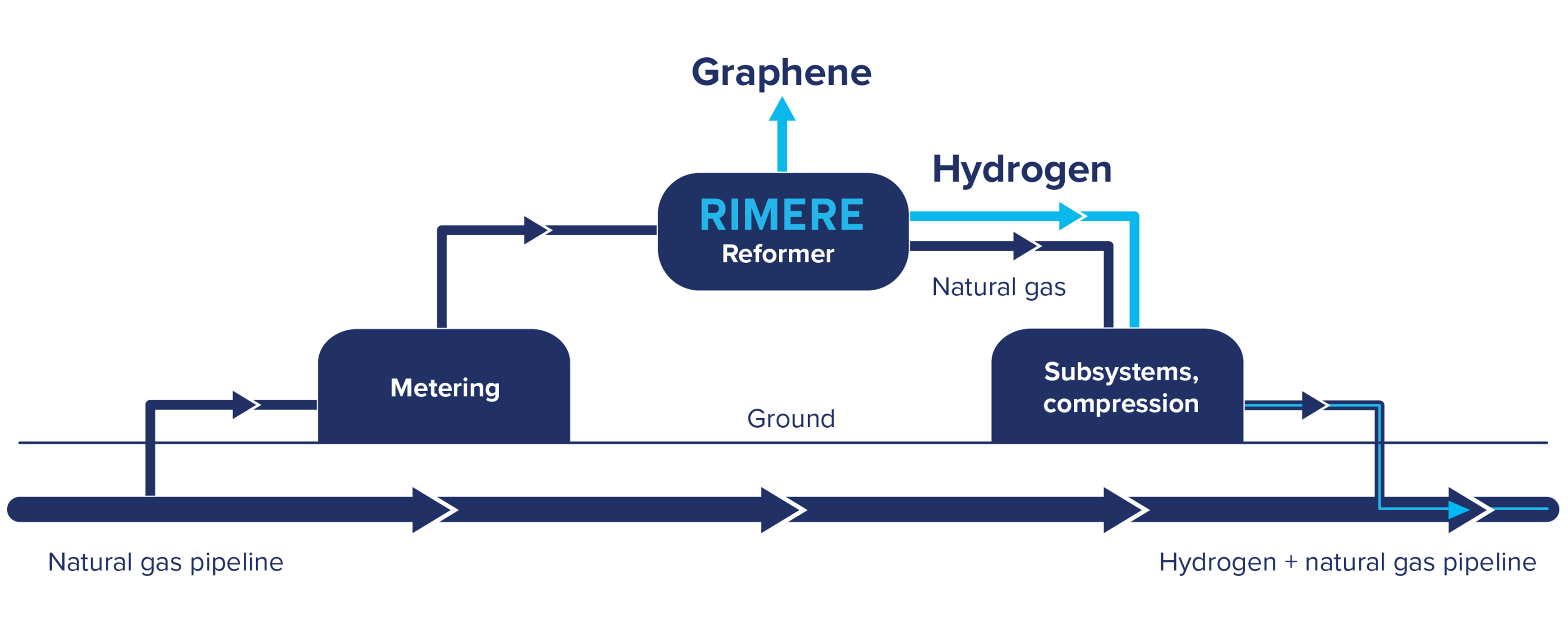

Reformer

The Reformer turns natural gas into clean hydrogen and graphene, without creating any CO2 emissions.

OPPORTUNITY

Deloitte forecasts the hydrogen market will grow to $1.4T per year by 2050.

The two most common methods for producing hydrogen are electrolysis and steam methane reformation (SMR), but both have their own drawbacks.

Electrolysis creates hydrogen from electricity and water. The problem is that it's power intensive and expensive.

SMR creates inexpensive hydrogen using natural gas, but generates CO2 emissions in the process.

SOLUTION

The Reformer is a cost-effective solution that transforms natural gas into zero-emission hydrogen. Unlike steam methane reformation, there’s no need to capture CO2 because the Reformer turns the carbon molecules into graphene, a co-product so valuable it creates a clear path to $1 per kg clean hydrogen.

Clean hydrogen

Produced without generating any CO2 emissions and requires less power than electrolysis.

Graphene

A unique, solid nanocarbon with extraordinary properties, often described as the wonder material of the 21st century.

When renewable natural gas (RNG) is used as the feedstock, our hydrogen achieves a negative carbon-intensity rating, making it substantially greener than even renewable electrolysis.

400-600 kg/day H2 unit in development

BLENDING APPLICATION

The Reformer’s blending application takes a slip stream of natural gas, extracts the high-value graphene, and then re-injects H2 and natural gas back into the pipeline.

If used on-site at power plants and other hard-to-decarbonize facilities, the hydrogen-rich gas stream can be easily introduced allowing boilers, burners, and other processes to emit less CO2.